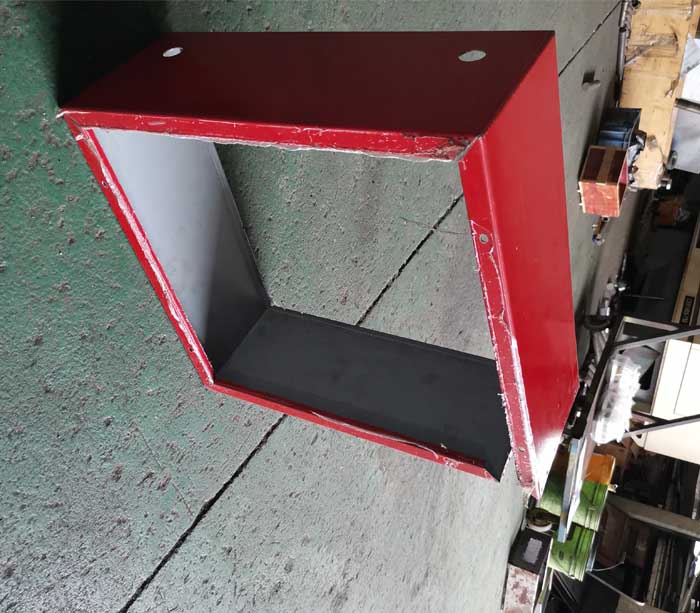

Automatic fire hose cabinet roll forming machine design for making fire hose cabinet parts & fire hose cabinet components.

https://www.superdamc.com

New design galvanized steel fire box production & surface-mounted cabinets production solution.

Equipment for producting galvanized steel /stainless steel fire hose cabinets, fire hose cabinet types.

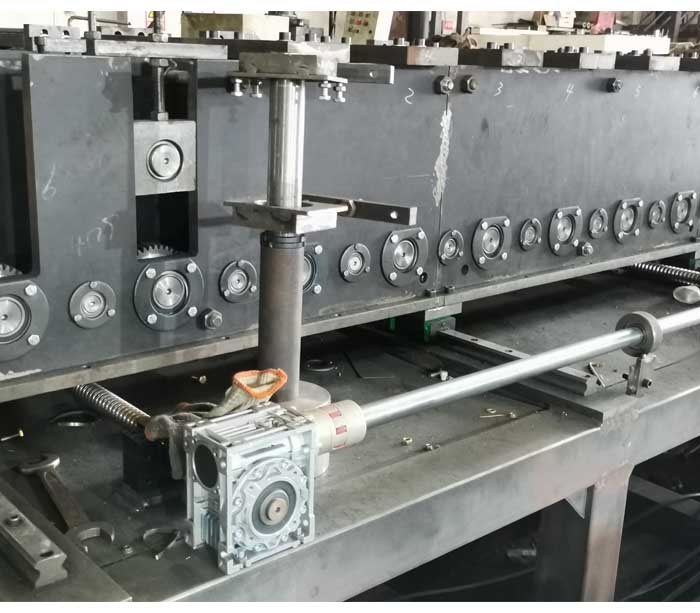

Big fire hose cabinet roll forming machine tooling

1, Fire hose cabinet production line technical parameters

| No. |

ITEM |

PARAMETER |

REMARK |

| 1 |

MATERIAL |

Type |

Cold-rolled strip steel, galvanized sheet |

|

| T.(mm) |

0.8-1.5mm |

|

| Yield Strength (Mpa) |

Q235 |

|

| 2 |

Forming product Width |

Customized |

|

| 3 |

Forming speed (m/min) |

6-13m |

Including hole |

| 4 |

Forming main power (KW) |

7.5 KW |

FYR |

| 5 |

Hydraulic power (KW) |

18.5 KW |

FYR |

| 6 |

Bending power (KW) |

3 KW |

FYR |

| 7 |

Voltage |

AC380V,50Hz,3P |

|

Fire hose cabinet production line process

Uncoiler →Straightening→servo feeder→Hydraulic press breach device → Guide device → roll forming machine → hydraulic punch → Bending enclosure (optional)→shear device (including knife)→ finished product rack

Fire box roll forming machine for production different size cabinet

Fire box parameters of the equipment

a. Power supply: 380V/50HZ/3PH, can customized as per user country.

b. Installed capacity: about 31kw.

c.Forming speed: 0-13m/mind.

d.Shearing method: Servo front shear

e. Drive motor: Unwinder motor 4KW.

leveling motor 2.2KW.

hydraulic punching cutting and hydraulic tensioning motor (two sets) 11KW+7.5KW. forming main engine 5.5KW.

servo motor 2KW

f. Floor area (approx.): length 24m × width 3m (host specification 7mX1.7m)

g Production line direction: from left to right (on the console facing the unit).

h. Equipment color: (customer selection)

i. Superda fire house box equipment design can meet 12 hours of continuous production

j. Operating environment

1: Power supply voltage: 380V ± 10% / three-phase four-wire,frequency: 50HZ Total power: about 31KW2: Environment Temperature: 0-40 ° C, relative humidity: 60-95% RH.